Cell Selection

Following factors play vital role in deciding final quality of a battery pack.

- Direct purchase from factory v/s purchase from trader.

- The manufacturer's quality control / a popular brand.

- Cell quality-For solar or inverter use v/s for EV use. Grade A+, A, or B

- Recently manufactured as per order v/s stock cells. More than one year old cells tend to degrade and available at discounts.

- Grouped or ungrouped.

The best quality can be achieved buying from a quality manufacturer, make to order, A grade for EV, assorted and grouped cells. They are expensive but they will deliver desired result and last longer.

Battery Sorting

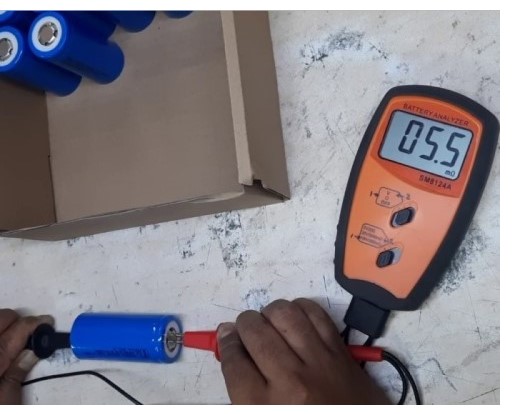

The manufacturer mostly do the grouping and sorting as per the grade. Traders mostly buy cheap cells in bulk and try to sell cheap in which case buyer needs to do grouping themselves or compromise with quality. Grouping is done on following parameters;

- The variation in capacity of all the cells should not be > 0.1%

- The impedence should be as low as possible and variation should not be > 10%. It should be further sorted to least possible difference. This can be minimised by special arrangement while making the battery pack

- It is always better to charge all the cells before building the pack. This will avoid balancing issues once the pack is made. This step can be avoided to save time with an active balancing BMS like Dexpress BMS. Such BMS keeps balancing automatically.

Packing with Holders

Each cell need to have free space around it for cooling. They need to be spaced out enough to allow air circulation and keep the size of the pack in limit and shape. Cell holder made of fire retardant and electrically neutral ABS material is available.

Holders keep the cells in place and prevent loosening of the welded contacts due to jerk and vibration while EV is on the move.

Hot glue application between cell and holder further strengthens the pack structure and prevent cell movement.

Spot Welding

- Spot welding is a process by which each cell is interconnected with other cells by nickel strips. They can also be connected using soldering technique. Spot welding is preferred because soldering needs very high temperature, which can cause damage to cell anode and cathode.

- Nickel strips are available as pure nickel and nickel coated. Pure nickel is very expensive compared to nickel coated. Nickel is a very good conductor of electricity compared to iron used in nickel coated. Nickel coated can rust and get heated due to higher resistance.

- It is neccessary to use professional grade spot welding machine for a good welding joint. There are cheaper options available, which doesn't produce long lasting weld and need repair in future.

Charging with Balancing

It is a must to charge the pack and balance all the rows before considering the pack fit for delivery to the customer. There may be insidences where BMS may fail or battery may refuse to balance due to some faulty cell.

Dexpress BMS is an intelligent BMS, which can detect imbalance and automatically balance while charge, discharge or at rest.

Active balancing system can increase the life of battery by 2 folds by keeping the battery health up to date. A fully balanced battery continue to provide range without much drop for long time.

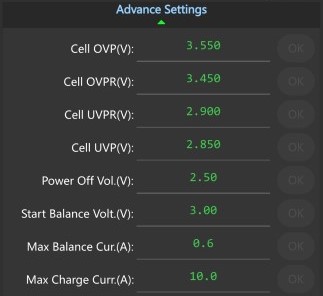

Setting up parameters

Many parameters can be defined using these settings to get the desired outcome from the battery pack. We can manage a good balance between range, performance and long life of the battery.

Maximum charging voltage is cut off at 3.55v, default is 3.65v

Discharge cut off voltage is set at 2.85v, default is 2.50v

DOD is maintained under 100% by Limiting charge and discharge cut off voltage.

Maximum charging current is limited to 10 Amp to avoid charging with any other charger.

Maximum discharge current is set to 30 Amp to prevent sudden surge to other components.

Battery Packing

Proper packing of the pack is important to achieve waterproofing along with cooling of the battery.

- Epoxy fiber glass plates are best to use as separator as well as all over covering. They are strong and fire proof. Some manufacturer use acrylic sheet to save money but it is dangerous as it melts with heat.

- It is covered with heat shrink PVC material for neat clean look as well as mild prevention from water.

- We at Dexpress seal with Aluminum Foil Self-Adhesive Tape at both ends for good waterproofing.

- We at Dexpress apply one more PVC covering to achieve further water proofing.